These flange tables cover flanges from 15mm (1/2") up to 600mm (24"). There are many common flange standards and these flange tables cover the most commonly found i.e. ANSI, PN and the old British BS10 Table D to K. Flanges are often used to connect valves into pipework making them easy to remove for maintenance. Flanges within the same standard can either be flat (commonly cast iron, ductile iron) or raised face (commonly cast steel and stainless steel). These flange tables cover the critical flange dimensions to help you identify the standard you have.

Flange Identification:

In most cases the flange specification will be hard stamped on the flange. In the case of existing plant, the information may not be readable and hence it is necessary to identify the flange by visual observation and by taking physical measurements.

a) Visual Observation: required to identify the type of flange and type of gasket used.

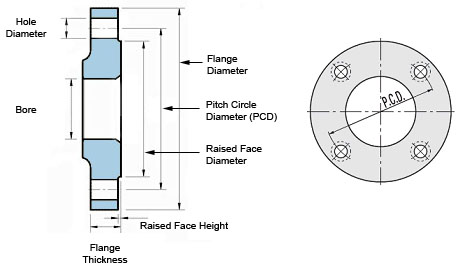

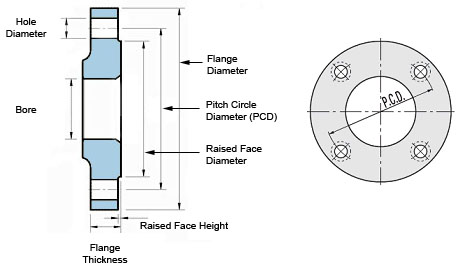

b) Physical Measurement: required to identify the nominal bore and the class of the flange. Check the number of stud bolts, stud bolt diameter, stud bolt Pitch Circle Diameter (PCD) and the flange thickness.

Note: Sometimes you will take measurements from a valve flange that don't match up to one particular standard. This typically occurs when the valve has been kept with blank undrilled flanges by the supplier and then drilled on ordering to the drilling you require. NB: This is a fairly common practice at the lower pressure end. A good starting point is to therefore match up the nominal size, the PCD, and the number of bolts first using the drop down selectors below. Then you need to make sure that the flange thickness and diameter is at least the same or greater than the measurements given in the table.